| There is a problem right now with this block. |

|

2-1. Initial Tear-Down in Tennessee

|

Initial Tear-Down in Tennessee

Restoration Begins - May 15, 2009

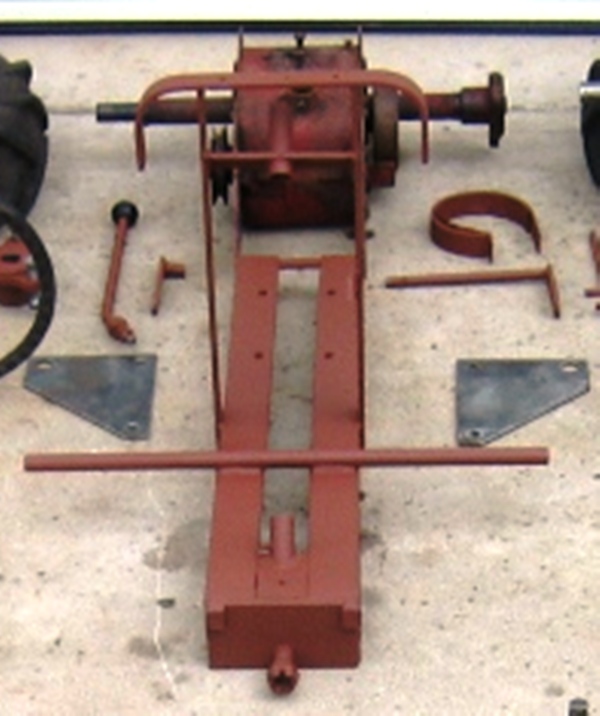

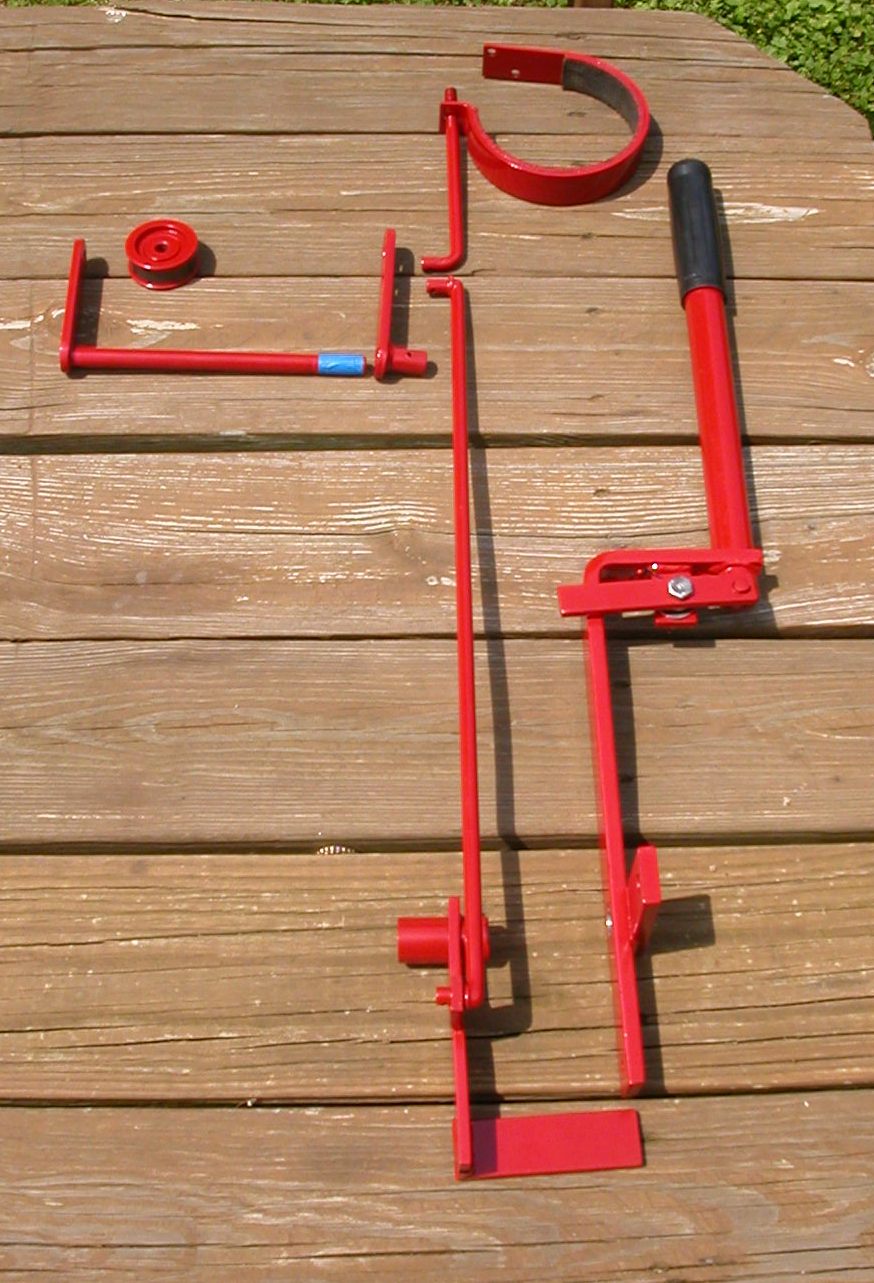

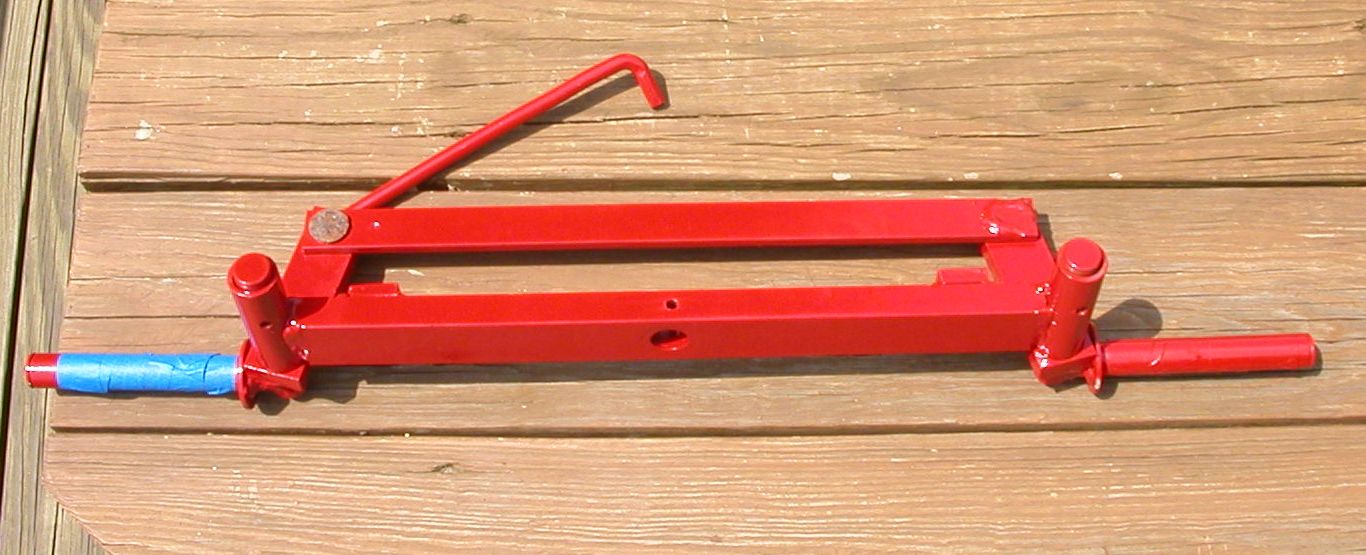

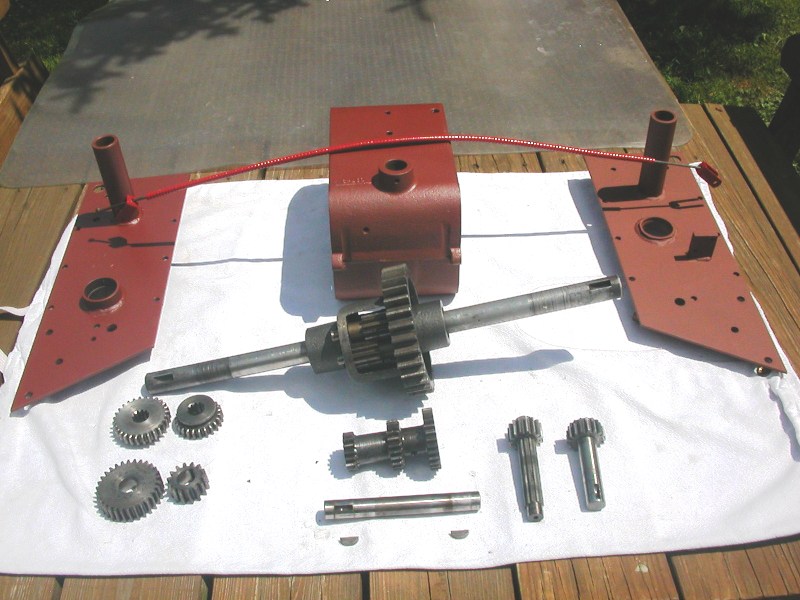

rn rn rn rn | rn I decided to start by disassembling the entire tractor so a determination could be made to the exact condition of each individual component part. The machine was power-washed and then completely disassembled. I then laid the parts out in exploded diagram view (as depicted above) for positional reference, as well as a starting-point picture. The following is the piece-by-piece assessment findings. rn Front and Rear Wheels: One rear Lug-Nut is missing. All wheels found to be in pretty good shape with just surface rust and very little pitting, all of the tires appear to be original vintage (or at the least very nearly original) and the rubber has no surface defects, structural defects, or dry rot (rare find). They appear to only require a good surface cleaning and refinishing with "Tire Black". Since they have been installed for so long, and I will not risk damaging the original tires, I decided to have them professionally removed when I returned to PA. A local (to me in PA) auto shop, experienced in racing and auto restoration, will dismount the Tires and bead-blast the rims. rn Frame: The frame had a total of 10 "extra" holes drilled into it in various places, mostly around the engine mounting area and hood-frame uprights. Since my brother-in-law Jason is a professional Iron Worker/Welder, has the welding equipment handy, and he just happens to be a few short miles away at the moment; he graciously "volunteered" to fill the holes for me. All of the "extra" holes were welded closed and the welds surfaced back to the level of the surrounding metal. No original welds were found to be defective or in need of reinforcement. The second picture below shows the frame welded, but not yet stripped. Frame was stripped, sand blasted, cleaned and primed. rn | rn rn rn  | rn  | rn  | rn  | rn rn rn | "Extra" Frame Holes | rn Frame Welded | rn Frame Primed | rn Frame Painted | rn rn rn | | rn | rn | rn | rn rn rn | Seat Pan, Spring, and Associated Parts: The Seat Pan was in surprisingly good condition, with just surface rust and no pitting or metal defects. An interesting note is that the seat pan had seven coats of paint, all "Linen" or white. Apparently the previous owners did not like sitting on a rusty seat, and all the paint protected the underlying metal quite well. The seat was stripped, cleaned, and primed. The seat spring on the other hand had been drilled twice at the rear of the spring and required welding the holes closed; welded, stripped, cleaned and primed. Seat Carriage Bolt and Nut were in good condition and only need the threads chased, surfaces stripped and cleaned and lightly primed. The Lift Cable Clamping Lug, Draw Bar Hitch Pin, and the Lift Cable were missing for the Draw Bar Hitch. | rn rn rn  | rn  | rn  | rn  | rn rn rn | Seat Pan As Found | rn Seat Pan Stripped | rn Seat Pan Primed | rn Seat Pan Painted w/ S-W Antique White | rn rn rn | | rn | rn | rn | rn rn rn | rn Attachment Lift Lever, Clutch Pedal, Idler, Brake Band and Associated Linkages and Parts: Attachment Lift Lever was badly repaired as previously stated; Lift Cable Missing; The retaining Shaft Collar is split at the set screw; replacements for all three required. All remaining parts were in excellent condition with no material defects or significant wear. Brake band shows >1/8" of brake material thickness remaining without signs of pitting or burning. All parts required only stripping and cleaning. The Clutch Pedal was the only part which required electrolysis cleaning due to shoe wear of the paint and heavy rusting in that area. Re-installation will require replacement of all small hardware items (i.e. correct nuts and bolts, washers, cotter pins, and Zerk fittings). Black (or Red if I can find them) Zerk Fitting Covers will be added as a non-original enhancement. rn | rn rn rn | | rn  | rn  | rn | rn rn rn | | rn Cobbled Lift Assembly | rn Completed Lift Assembly | rn | rn rn rn | | rn | rn | rn | rn rn rn | Front End (Axle) and Steering Components: The Front End (the Axle), though well rusted in the first image below, shows very little surface wear or pitting, and no pivot hole wear or top surface wear. The Castle Nut was unbroken and hard edged (no previous wrench stripping), there is no wear on the axle pivot shaft, and the Front Spindles fit closely in the spindle tubes. The wheel shafts on both front spindle show negligible wear at the bearing contact points. Steering Lug pivot holes are round and unworn, but both both "Clevis Pin, Steering" parts are significantly worn and cannot be reused in the restoration. Both will need to be manufactured and replaced. All Zerk Fittings and Retainer Rings will require replacement as well.rn The steering Tie Rod is unworn but slightly bent in the middle, and the Steering Lug shows a little wear on the top corners (steering to the extreme right and left causes the lug to contact the bottom of the frame, which causes minor wear to the corners of the lug block) which will require a small amount of sanding to equal the contour of both sides. The Steering Rod has no wear and is straight. rn The Steering Wheel is slightly bent at the hub, but can be straightened; and the steering wheel grip has three cracks in the plastic which must be repaired or the steering wheel replaced. Also, the Roll Pin is not easy to remove. I decided to wait until I am home and have access to a press before attempting removal of the wheel. All other parts stripped, cleaned and primed, except steering wheel and Steering Rod. rn | rn rn rn  | rn  | rn  | rn rn rn | Front End as Removed | rn Front End Primed | rn Completed Front End Assembly | rn rn rn | | rn | rn | rn | rn rn rn | | rn | rn | rn | rn rn rn | 5003 Uni-Drive Transmission, Rear Wheel Hubs, and Shifter Components: No Work Performed on Transmission at this time (as of 6/25/2009) except removal of the external components. The Shift Handle, Drive Pulley, Brake Pulley, Idler Pulley, Idler Arm and Clutch Arms have been removed, stripped, cleaned, and primed. Unfortunately, like a Dumb-Ass, I broke the side off the 1611 Drive Pulley while removing the Idler Arm. The Drive Pulley will require a replacement part. Idler Pulley bearings were flushed and bearings inspected, all good. The Idler Pulley will require repacking before re-installation (What Grease Type ???), and all hardware and Cotter Pins replaced with stainless steel parts before reassembly. | rn rn rn  | rn  | rn  | rn  | rn rn rn | Rebuild Begins | rn Transmission During Rebuild | rn Finished Transmission | rn Installed | rn rn rn | | rn | rn | rn | rn rn rn | rn Engine and Exhaust System Parts: All parts missing from tractor. A choice must be made between the Kohler's K-90 & K-91 and the Clinton B-1290 engines. The engine procured will determine which size pipe and elbows are needed for the exhaust system (Kohler uses 1ea -3/4" x 90° and 1ea - 3/4" x 45° Elbows vs. Clinton 2ea-1/2" x 45°, both use different pipe diameters and lengths), and exhaust system pipe will be procured locally, pieces cut to the required lengths, and threaded as required. All exhaust parts must be manufactured from heavy-wall steel pipe, cut to required lengths per engine installed, and threaded per the parts breakdown. Muffler will also be procured locally. rn Hood, Fuel Tank, and Associated Hood Components: All components are missing and will require replacement parts acquisition. More information later in the article. Replacement parts to be acquired June 01, 2009 from Vince-63Panzer rn Snow Blade and Associated Parts: The Snow Plow Blade has very heavy wear to the left and right bottom corners. The previous owner did not take care to flip the sacrificial plate when it wore to the point of dragging the Blade on the ground. The right Skid Shoe was missing and replaced with a 2 1/2 pound barbell weight and Nut/Bolt combination. Skid Shoe and Sacrificial Strip will require replacement. The Blade Bar appears to be a home made affair and will also require replacement. All other components stripped, cleaned and primed. Plow Blade is currently awaiting welding prior to refinishing. rn | rn rn rn | | rn | rn | rn | rn rn rn

|

Last Updated: 2010-03-08 08:57:08 (11754 views)

|

|